Max tube factory is the top manufacturer of precision tube and weld tube in China .

It was set up in 1981 , in order to meet the development of the market, continue to employ talents , update equipments,

now it move into the new plant in 2006 .

Area of plant 40000 ㎡ , more than 350 employees .

Anual capacity: 90000 tons

Certificate: TS16949 /ISO9001

1.Main Production equipment

2.Testing facilities

Universal testing machine

Spectrum machine

Roughness tester

Contour machine

Brinell-Rockwell-Vickers hardness

Metallurgical microscope

Laser diameter measuring instrument

Eddy current testing facility

T.S.,Y.S., Elongation,Flaring, Flatteing, Fending

Chemical composition

Metallurgical test

Hardness

Roughness

Contour dimension

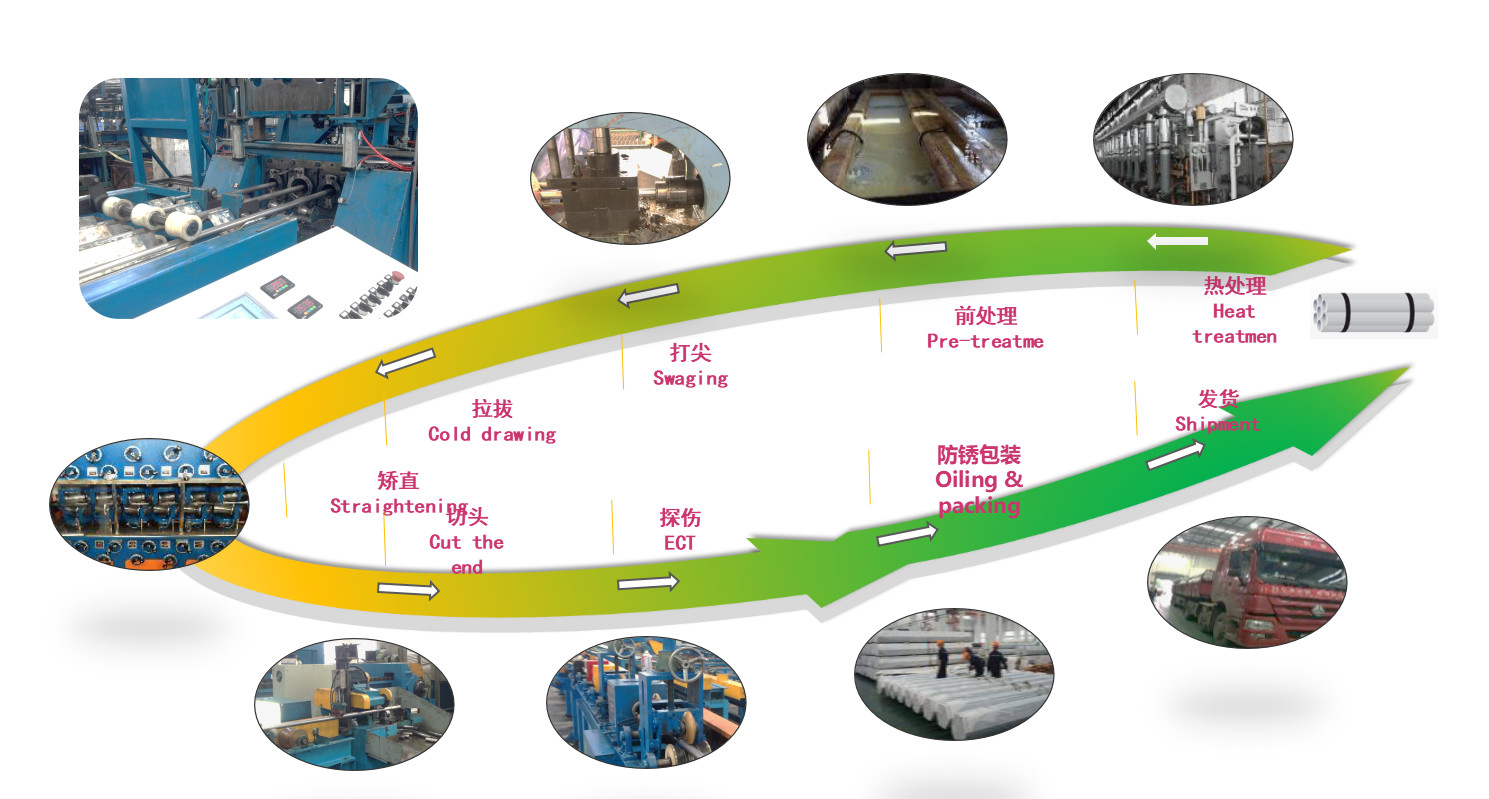

3.CDW tube production

4.Tube Size

CDW cold drawn weld tube size range

OD:Φ14~Φ76mm

Thickness:0.8 ~ 5mm

Cold-rolled precision seamless tube size

OD:Φ14~Φ220mm

Thickness: 0.8~ 16mm

ERW Tube size range

OD:Φ16~Φ89mm

Thickness:0.8T ~ 4.5mm

OD:T≥10(Common)

OD:T≥ 8(Special)

5.Standards& application

Standards:

GB/T8713

GB/T8713 <precision ID seamless tubes for hydropneumatic purpose>

GB/T3639

GB/T3639 <cold-rolled and cold drawn precision seamless steel tubes>

DIN2393/2394

DIN2393/DIN2394 <precision welded tubes>

ASTM-A513

ASTM-A513 <ERW carbon steel and alloy steel mechanical tubes>

EN10305-2

EN10305-2 <welded cold drawn tubes>

EN10305-6

EN10305-6 <welded cold drawn tubes for hydraulic and pneumatic power system>

JIS-G3445

JIS-G3445 <carbon steel tubes for machine structural purpose>

Or produce according to customer’s requirement

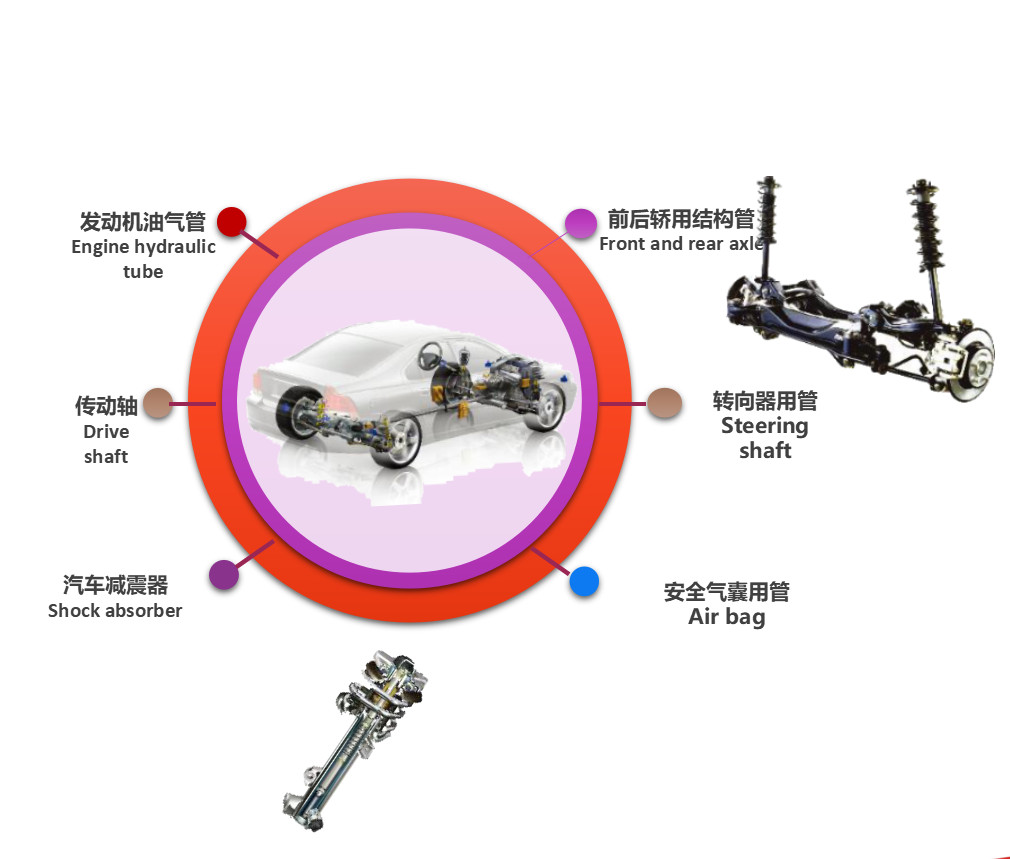

Application

Front and rear axle

Steering shaft

Air bag

Shock absorber

Drive shaft

Engine hydraulic tube