| Outer Diameter: | Ø 6mm-35mm |

| Total Length: | 100mm -650mm |

| Steel Material: | SAE1035/SAE1045 |

| Chrome Thickness: | 10~25 μm |

| Chrome Hardness: | 900 HV Min |

| Roughness: | Ra 0.1 Micron Max |

| Straightness: | 0.02/400mm |

| Yield Strength | According to the steel material and customer requirement |

| Tensile Strength | According to the steel material and customer requirement |

| Elongation | According to the steel materia |

| Bend Test | According to customer requirement |

| Supply condition: | 1. Hard Chrome Plated |

| 2. QPQ Treatment | |

| 3. Induction Hardened | |

| 4. Dehydrogenation & Tempered |

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, shopper supreme" for Europe style for China Well Ground & Polished, Hard Chrome Plated Rods High Performance, Durability Trouble-Free Operation with Superior Design and Quality Hydrau Hydraulic Cylinder, Our merchandise have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. On the lookout ahead to create up a fantastic and long lasting cooperation along with you in coming foreseeable future!

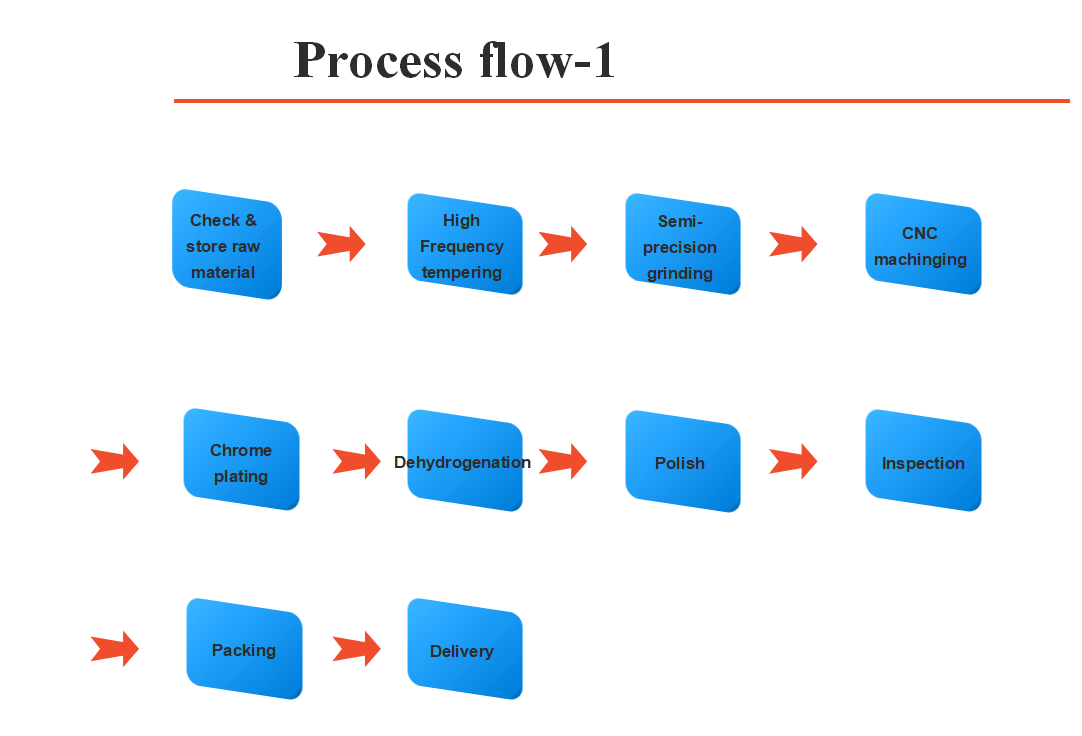

1. process introduction. The piston rod is hard chromium plating on steel substrate surface coated with a thick layer of chromium plating and its thickness is in commonly 10 to 30 microns , using the characteristics of chromium improve parts’ performance ,such as hardness, wear resistance, heat resistance and corrosion resistant . The process features of hard chrome plated piston rod: 1) the cathode current efficiency is as high as 25% ~ 35%, and the deposition rate is very fast. 2) high hardness (900 ~ 1200HV), uniform and dense network cracks, good abrasion resistance;Microcracks can be produced, and the number of microcracks can reach 800-2000 pieces/cm (according to the need), and improve the anti-corrosion ability. 3) good dispersion ability of the plating bath, uniform thickness of the coating, not easy to produce the phenomenon of rough blister tumor, and the appearance of chromium layer is bright and smooth; 4) the coating has strong bonding strength with the substrate, and the pretreatment is similar to the traditional technology, and the operation is easier than the traditional process; 5) the content of trivalent chromium in the bath is allowed to be wide, and it usually does not need to discontinue electrolysis for trivalent chromium; 6) the plating solution contains no fluoride, no rare earth elements, and no corrosion of the workpiece without low power. 2.Process flow. 1). Process flow of hydraulic piston rod. Connecting rod using 35 steel, processing technology: cold-drawn forming a turning a continuous medium frequency induction hardening, a cylindrical grinding, a fine grinding cylindrical a fine grinding cylindrical shearing section.at finishing a plating chromium to hydrogen tempering shearing section.at fine grinding.In order to improve the surface quality and corrosion resistance of piston rod, super finishing process was added before chrome plating. 2). Piston rod plating process. Inspection before plating - pack hanging fixture - chemical degreasing, electric lift oil - water - activation pickling - water washing- the moment, the piston rod chromium plating, recycling water - water washing - unloading hanging fixture - inspection

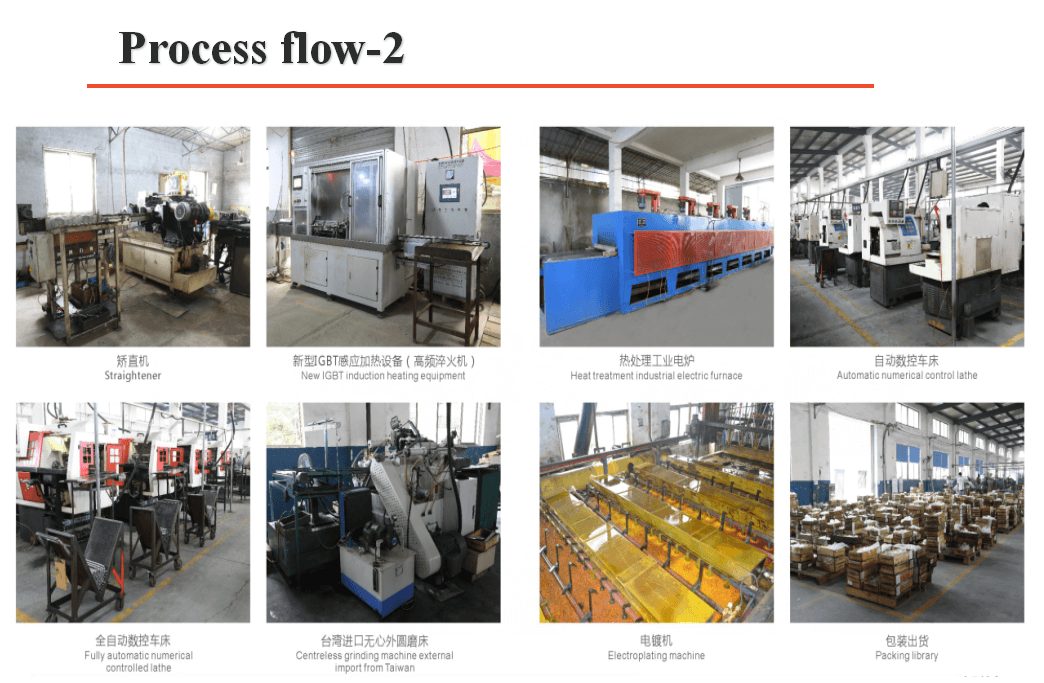

Equipment

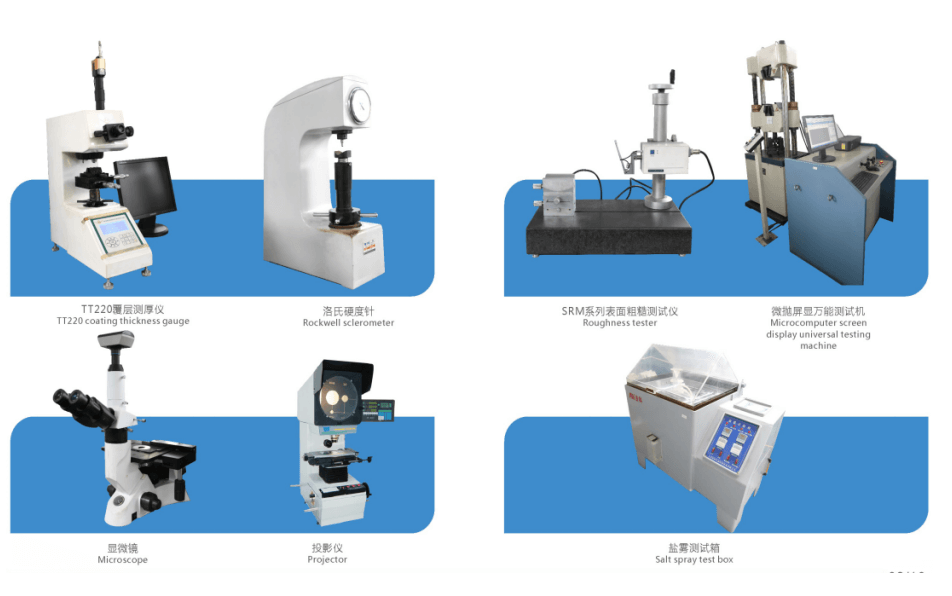

Equipment  Test center

Test center  3.Packing of piston rod Each rod will be oil treatment first , then separate by layer and layer , one by one . Each small box use VCI bag to protect from rust , then box into wooden pallet . The weight and size can be made according to customer requirement .

3.Packing of piston rod Each rod will be oil treatment first , then separate by layer and layer , one by one . Each small box use VCI bag to protect from rust , then box into wooden pallet . The weight and size can be made according to customer requirement .

| Q1. Are you a Manufacture or Trading Company? |

| A1:We are manufacturer and we have licence to export auto parts, we have been in this line for 10 years |

| Q2. What kinds of parts can you supply? |

| A2: 1.Shock absorber 2. Piston rod 3. Oil seal 4. Rubber parts 5. Powder metallurgy parts etc. |

| Q3. What is your production Lead Time? |

| A3:Usually it’s 30 calendar days, but it depends on PO. Quantity. |

| Q4. What is your payment way? |

| A4:We accept payment by western union, T/T, L/C. Normally, 30% deposit in advance, 70% balance before shipment |

| Q5. Dispatch Port ? |

| A5:Guangzhou, Ningbo, Shanghai |

| Q6. What other service can you offer? |

| A6:OEM service, welcome to send us the design drawing to develop a new product line. Customized service, we can help you to design your packing. |

| Q7. How can I get the warranty? |

| A7:During the warranty period,any products damaged because of the quality problem can be changed for free. |

| Q8: How can I get your sample ? |

| A8: First you tell us which size needed , then we try to find it from our current model , if there is current mold , the samples will be free , if there is no current mold , we can supply similar size or make new mold . |